I-Pelletising, inqubo eyinhloko ekukhiqizeni imikhiqizo yepulasitiki, igxile ekusetshenzisweni kabusha nasekukhiqizeni ama-pellets epulasitiki, okuyizinto ezibonakalayo zezinhlelo zokusebenza ezihlukahlukene ezifana nokukhiqizwa kwefilimu, ukubunjwa komjovo kanye nokukhishwa. Kunenqwaba yobuchwepheshe be-pelletising obutholakalayo, phakathi kwabo umugqa wokukhiqiza we-bi-stage pelletising wefilimu ugqama njengokuhlonyiswa okwengeziwe ngokusebenza kahle nokusebenza kahle ukukhiqiza ama-pellets asezingeni eliphezulu asuka ezintweni ezilahlwayo zepulasitiki.

Ukuguqula izinto ezisetshenziswayo ezinjengama-plastiki angcolile zibe ama-pellets amancane, afanayo kuyinqubo yokugaya, futhi yonke inqubo ye-pelletising ihlanganisa, ukuphakela, ukuncibilika, ukukhipha, ukupholisa nokusika ukuze kudale ama-pellets angaphathwa kalula, athuthwe futhi acutshungulwe ezigabeni ezilandelayo zokukhiqiza.

Ubuchwepheshe be-Pelletizingingahlukaniswa ngobubanzi izigaba ezimbili: i-pelletising yesiteji esisodwa kanye ne-pelletising enezigaba ezimbili. I-pelletising yesiteji esisodwa isebenzisa i-extruder eyodwa ukuze incibilike into futhi yenze ama-pellets, kuyilapho i-pellets enezigaba ezimbili isebenzisa ama-extruder amabili, okuvumela ukulawula okunembayo kwenqubo yokuncibilika nokupholisa, okuholela kumapellets ekhwalithi ephezulu.

Ifilimu enezigaba ezimbiliumugqa we-pelletisingyakhelwe ukucubungula amafilimu epulasitiki afana ne-polyethylene (PE) ne-polypropylene (PP). Ubuchwepheshe bufaneleka ngokukhethekile ukugaywa kabusha kwamafilimu epulasitiki angemuva komthengi, okuvamise ukuba nzima ukuwacubungula ngenxa yokuminyana kwawo okuphansi nokuthambekela kokunamathelana.

Ukondla kanye nokucubungula kwangaphambili kuhilela ukuphakela kuqala uhlelo nge-plastic film scrap, evame ukudatshulwa ibe yizicucu ezincane ukuze kube lula ukuphatha nokucubungula. Ukwelashwa kwangaphambi kwesikhathi kungase kuhlanganise nokomisa okokusebenza ukuze kukhishwe umswakama, okubalulekile ekuncibilikeni okuphezulu kanye ne-pelletising.

Esigabeni sokuqala, ifilimu yepulasitiki ehlisiwe ifakwa ku-extruder yokuqala, efakwe isikulufu esincibilikisa izinto ngokugunda ngomshini nokushisa. Upulasitiki oncibilikisiwe ube usuphoqwa ngesikrini ukuze kukhishwe ukungcola futhi kuqinisekiswe ukuncibilika okufanayo.

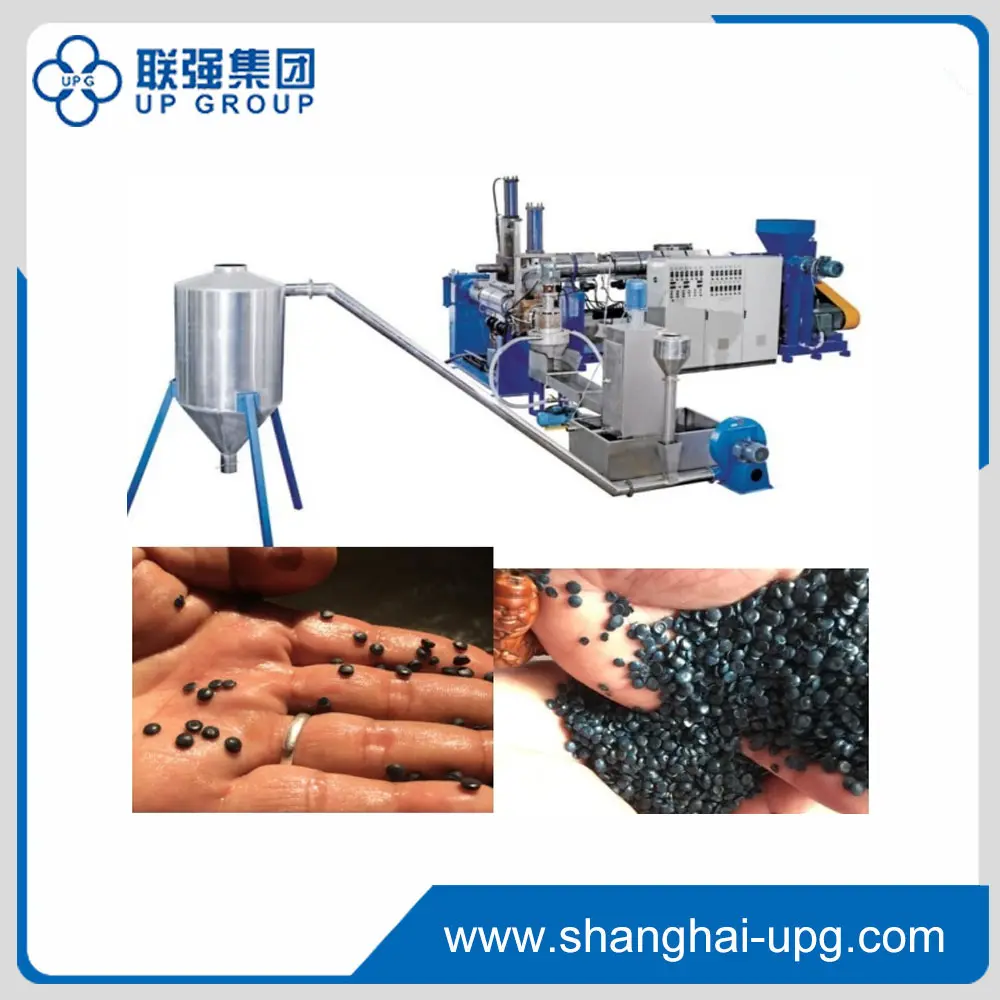

Faka, sicela ucabangele lo mkhiqizo wenkampani yethu,I-LQ250-300PE Ifilimu Ye-Double-Stage Pelletizing Line

Kusukela ku-extruder yokuqala, izinto ezincibilikisiwe zidlulela ku-extruder yesibili, isiteji esivumela i-homogenisation eyengeziwe kanye ne-degassing, okubalulekile ukususa noma yikuphi ukuguquguquka okusele noma umswakama ongase uthinte ikhwalithi ye-pellet yokugcina. I-extruder yesibili ivame ukuqhutshwa ngesivinini esiphansi, esiza ukugcina izakhiwo zepulasitiki.

Ngemuva kwesigaba sesibili sokukhipha, i-pelletiser isetshenziselwa ukusika ipulasitiki encibilikisiwe ibe ngamapellets, angapholiswa ngaphansi kwamanzi noma ngomoya, kuye ngezidingo ezithile zenqubo yokukhiqiza. Ama-pellets akhiqizwayo afana nosayizi nokuma futhi afaneleka ukusetshenziswa okuhlukahlukene.

Uma ama-pellets esebunjiwe, adinga ukupholiswa futhi aqiniswe, bese omiswa ukuze asuse umswakama owedlulele. Ukupholisa kahle nokomisa kubalulekile ukuze kuqinisekiswe ukuthiama-pelletsbalondoloze ubuqotho babo futhi bangafihli.

Okokugcina, ama-pellets apakishwa ukuze agcinwe noma athuthwe, inqubo eklanyelwe ukunciphisa ukungcola kanye nokuqinisekisa ukuthi ama-pellets asesimweni esifanele ngaphambi kokusetshenziswa.

Ngezansi ezinye izibonelo zezinzuzo zomugqa wezigaba ezimbili we-pelletising wamafilimu:

- Ikhwalithi ephezulu ye-pellet:inqubo yezigaba ezimbili ivumela ukulawulwa okungcono kwenqubo yokuncibilika nokupholisa, okuholela kumapellets ekhwalithi ephakeme anezakhiwo ezithuthukisiwe zomzimba.

- Ukususwa kokungcola okuphezulu:Inqubo ye-extrusion yezigaba ezimbili isusa ngempumelelo ukungcola kanye nokuguquguquka, okuholela ekuhlanzeni, ama-pellets angaguquki.

- Ukuhlukahluka:Ubuchwepheshe bungacubungula anhlobonhlobo amafilimu epulasitiki, awenze afaneleke ezinhlobonhlobo zokugaywa kabusha.

- Ukusebenza kahle kwamandla:Amasistimu e-Bipolar ngokuvamile aklanyelwe ukusebenzisa amandla amancane kunezinhlelo zesiteji esisodwa, okuwenza abe inketho esimeme kakhudlwana.

- Isikhathi sokuphumula esincishisiwe:ukuklama okuphumelelayo komugqa wefilimu we-bi-stage pelletising kunciphisa isikhathi sokuphumula ngesikhathi sokukhiqiza, okuholela ekwandeni kokukhipha kanye nokukhiqiza.

Ubuchwepheshe be-Pelletizing budlala indima ebalulekile ekusetshenzisweni kabusha nasekukhiqizweni kwemikhiqizo yepulasitiki. Imigqa ye-pelletising yezigaba ezimbili yefilimu imelela intuthuko enkulu kulo mkhakha, ukuthuthukisa ukusebenza kahle, ikhwalithi kanye nokuhlukahluka. Njengoba isidingo sezixazululo zepulasitiki esimeme siqhubeka nokukhula, ukubaluleka kokusebenza ngempumeleloubuchwepheshe be-pelletizingizokwanda nsuku zonke. Ngokutshala izimali ezinhlelweni ezithuthukisiwe ezifana nemigqa ye-pelletising yefilimu enezigaba ezimbili, abakhiqizi bangakwazi ukufaka isandla ekusaseni elizinzile ngenkathi behlangabezana nezidingo zamakhasimende abo, ngakho-ke uma unesithakazelo kumigqa ye-pelletising yezinyathelo ezimbili zefilimu, sicela ungangabazi ukuxhumana nenkampani yethu.

Isikhathi sokuthumela: Dec-30-2024